Transform Your Dental Lab with MyStructo

Structo’s software platform is designed to power the next generation of digital manufacturing. By integrating MyStructo for production management and Phantom for automated file preparation, it connects every step of the workflow into one seamless system. From automating complex processes to enabling fleet-wide monitoring and real-time insights, our platform helps manufacturers scale efficiently while maintaining precision and consistency.

The result: lower cost-per-part, higher equipment utilization, and increased production capacity—delivering measurable business value whether you’re producing dental appliances, consumer goods, or industrial components.

MyStructo is a comprehensive management software designed to oversee your entire manufacturing process, allowing you to transition from managing individual machines to orchestrating a full fleet of production assets.

Cloud Connectivity

Access your printers anywhere.Workflow Automation

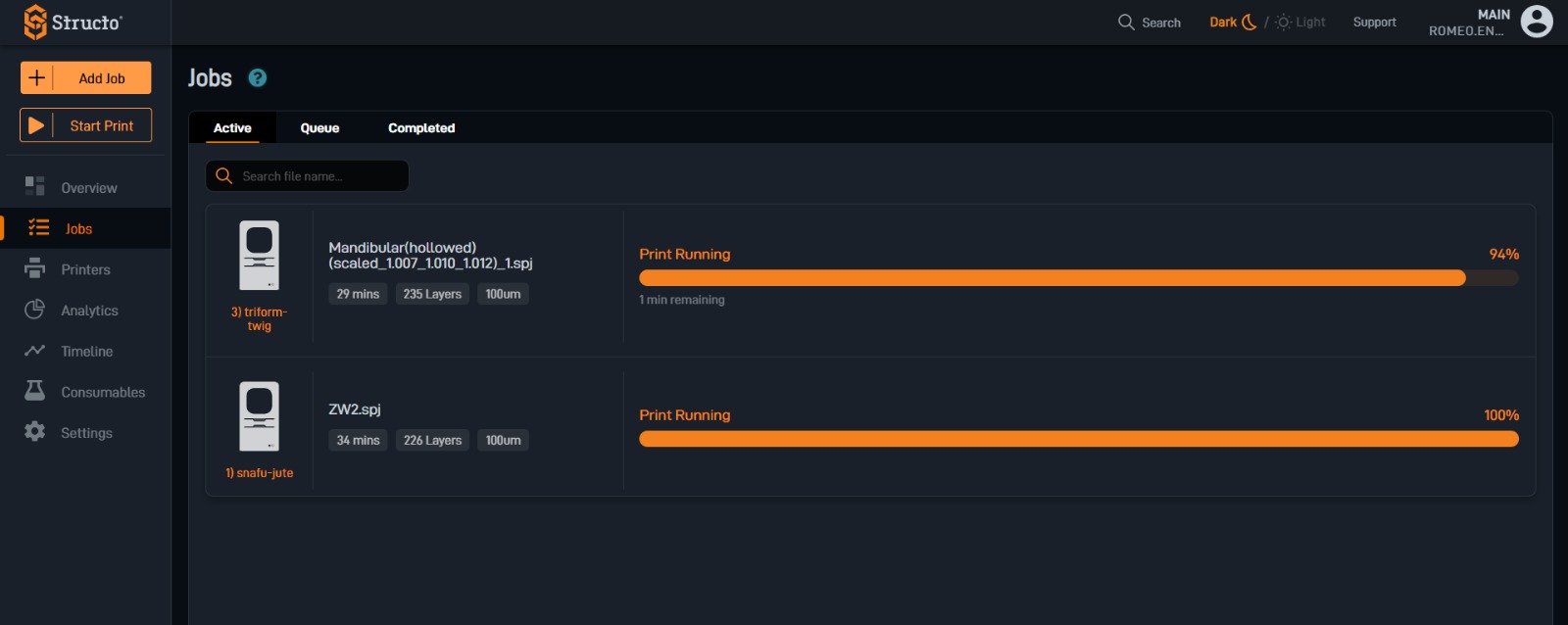

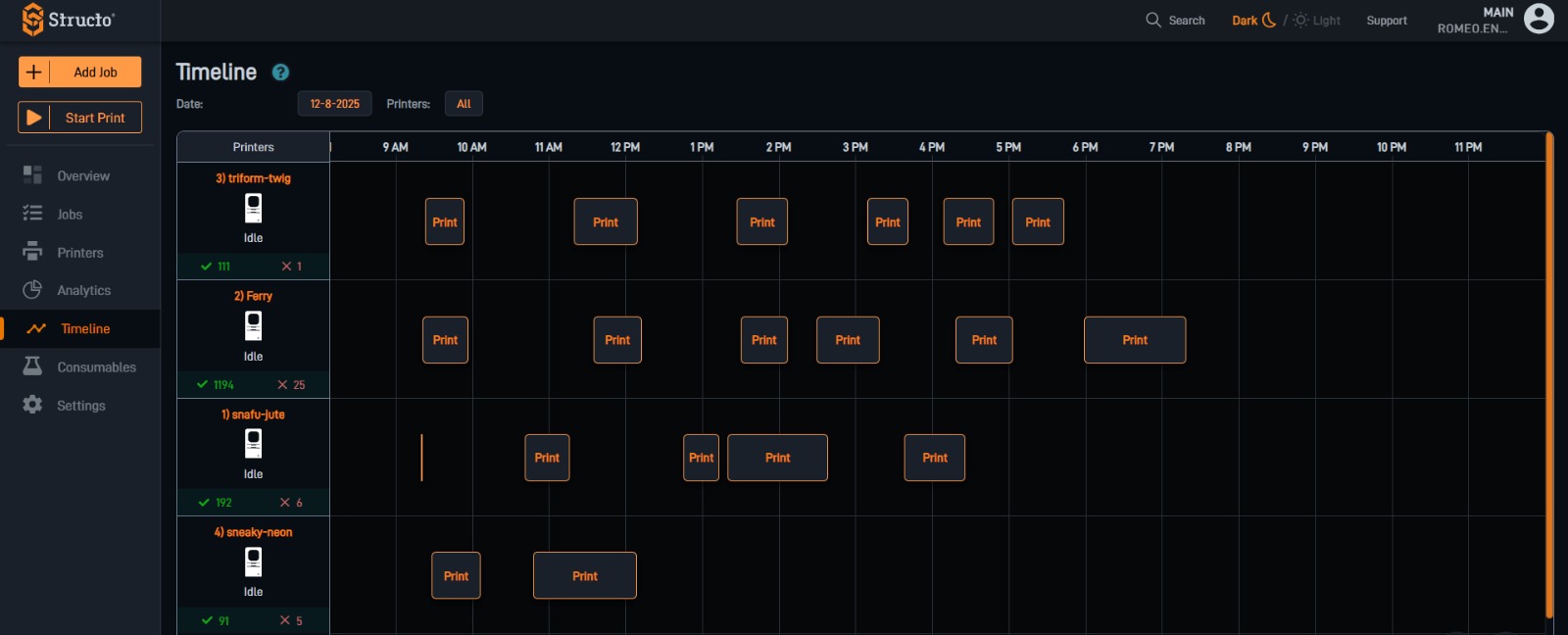

Schedule and manage jobs effortlessly.Real-time Monitoring

Track print progress live.Secure Data Handling

Enterprise-grade protection.Analytics Dashboard

Optimize usage and efficiency.Multi-Device Support

Works across desktops, tablets, mobiles.Save Time

Reduce manual prep.High-Speed, High-Accuracy Processing

Delivers consistent, quality prints at production speedsScale Easily

Manage multiple printers/sites.Smarter Decisions

Data-driven insights.Improve Accuracy

Consistent quality across jobs.Lower Costs

Optimize printer usage.Our MyStructo platform is validated by its proven performance in demanding, real-world environments. The technology is trusted by large, industry-leading dental laboratories who report significant increases in production efficiency and overall capacity. It also serves as the essential manufacturing backbone for modern, high-growth direct-to-consumer (D2C) brands that depend on the ability to efficiently produce thousands of unique products daily.

Perhaps the most dramatic validation came during the COVID-19 pandemic, when we rapidly pivoted to manufacture over 1 million sterilized, FDA-registered medical testing swabs per week, proving the platform’s industrial-grade scalability and ability to meet strict regulatory and quality management standards. This was only made possible thanks to versatility and fast deploy-ability of Mystructo as a Fast scale production environment enabler .

Who MyStructo Best Serves

MyStructo is engineered to scale with your business, offering powerful tools for operations of all sizes. While it is the ideal command center for high-volume production environments, it also delivers significant value to smaller operations by simplifying daily tasks.

Our primary users include:

- High-Volume Dental Laboratories & Industrial Producers: Labs and manufacturing hubs focused on maximizing throughput, managing fleets of equipment, and leveraging production data to optimize cost-per-part and turnaround times.

- Multi-Location Clinic Groups & DSOs: Dental Service Organizations (DSOs) and clinic chains that are in-sourcing production and require centralized control and consistency across multiple locations.

For smaller clinics and labs: MyStructo eases workload complexity by providing remote oversight and real-time status updates. This allows clinicians and technicians to manage production with fewer manual check-ins, freeing them up to focus on patient care and other high-value tasks.

Addressing Your Key Challenges

Our software is designed to solve the most common pain points in a high-volume production environment.

| If You’re Struggling With… | Our Solution Is… | The Benefit to You Is… |

|---|---|---|

| High labor costs and a shortage of skilled CAM technicians. | Phantom Software | Automate repetitive file preparation and free your expert technicians to focus on high-value design work and complex cases. |

| Production bottlenecks and equipment downtime. | MyStructo Software | Manage your entire fleet in real-time to maximize uptime and increase capacity without a proportional increase in staff or footprint. |

| Inconsistent production quality and material waste. | Phantom Software | Our co-developed software works in perfect sync to deliver repeatable, predictable results, reducing costly failures. |

| A lack of data on production efficiency. | MyStructo Software | Get real-time monitoring and analytics to optimize asset utilization, make data-driven decisions, and scale operations efficiently. |