3D Printers & Post-Processing Equipments

ST-32

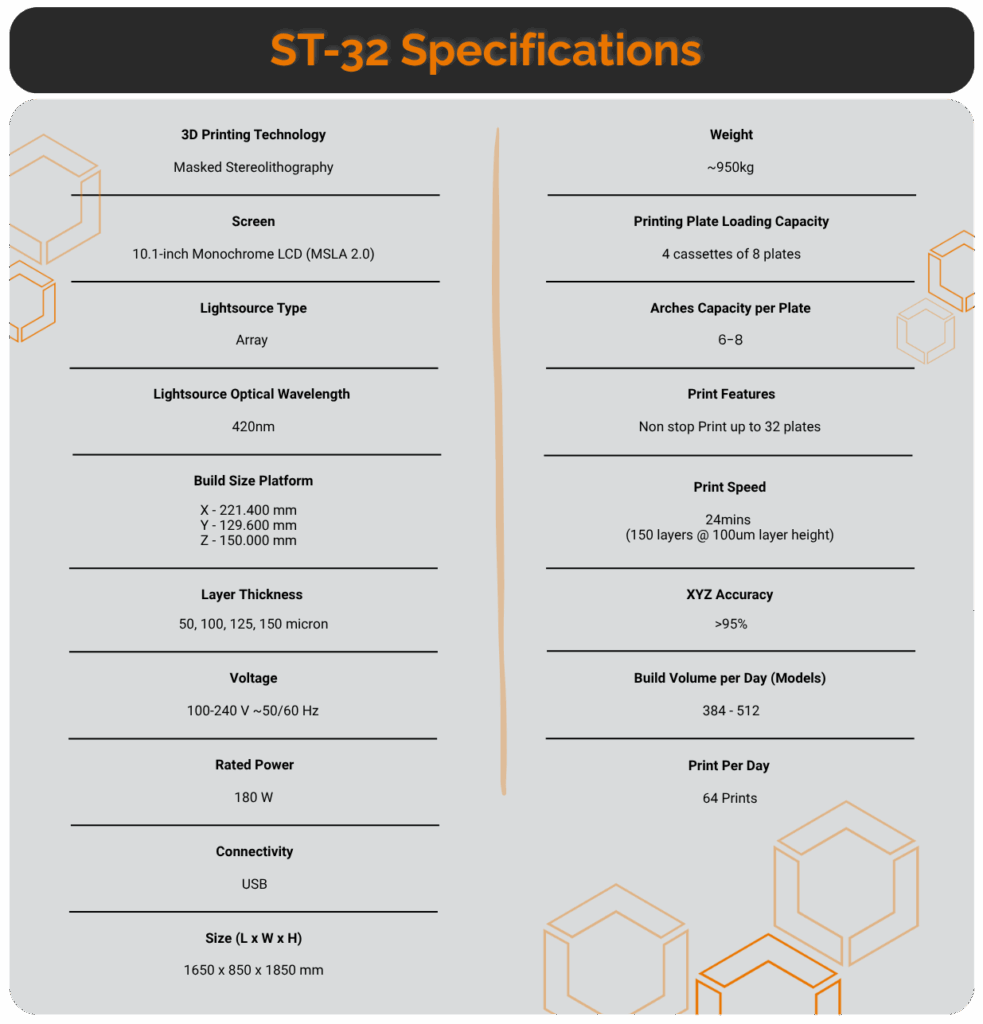

Structo ST-32 is a semi-automated MSLA 2.0 3D printer engineered for lights-out manufacturing of high-volume clear aligner models in dental and orthodontic laboratories. Leveraging advanced automation, the ST-32 minimizes manual intervention, enabling continuous, round-the-clock production.

With its automated platform replacement system, the ST-32 can print up to 32 EZrelease platforms in a single cycle, requiring human interaction only once every 15 hours. This efficiency is achieved through features like resin refill and filtration, part traceability, and remote print monitoring via a 2 MP Wi-Fi camera.

The printer’s build area measures 222 x 129 x 100 mm, and it delivers a printing accuracy of 95% at 100 microns, making it ideal for producing precise dental appliances. Its footprint is 1600 x 850 x 1800 mm, accommodating the needs of high-throughput labs.

Key Features

Minimal Human Intervention

Fully automated processes for reduced operator involvement.Manpower Optimization

Maximizes workforce efficiency.No Downtime Between Prints

Continuous production for uninterrupted output.Enhanced User Experience

Streamlined interface for easy operation.Increased Print Capacity

Handles larger production volumes efficiently.Technical Specifications